Dynamite or a crane with a wrecking ball can undoubtedly knock down a structure quickly, but for many projects, a more precise approach is necessary. With those destructive methods, you may not have a lot of choice about what gets destroyed, and there are many other downsides.

Precision demolition allows more control over taking a structure apart, decommissioning a property, or making changes to a structure. Here is what you need to know about precision demolition as well as five different types of precision demolition methods and the advantages of each one.

What Is Precision Demolition?

Precision demolition is also referred to as “controlled demolition.” Instead of blowing something up or knocking it down, it involves a more calculated approach to deconstruction. This can protect the integrity of the rest of the structure if only certain parts need to be removed or altered.

It can also save money because this type of demolition can produce less waste than traditional methods. Finally, precision demolition is a safer and more environmentally friendly approach to the deconstruction or alteration of a structure.

4 Types of Precision Demolition and the Advantages of Each

Depending on the size and scope of the project, different types of precision demolition methods may be used. Here are five different types of precision demolition methods and the advantages of each.

Diamond Wire Sawing

Diamond wire sawing is a core component of Bluegrass Bit’s precision demolition services. We can configure and deploy these versatile saws to cut a variety of materials in some of the most extreme environments, excelling at underwater cutting.

We custom build and test our diamond wire saws in-house, allowing us to deliver the most precise concrete and metal cutting services possible. The diamond beads along the wire do most of the work, creating friction that cuts through hard materials.

Diamond wire saws are so versatile that they can be used to depths of up to 5,000+ feet. They are also a cost-effective solution compared to many other demotion methods.

Bluegrass Bit recently used diamond wire sawing in support of Denver’s Gross Reservoir Expansion project. We removed the dam’s ogee crest in Project Phase 1 by sawing through the dam’s 28’ width.

Metal Cutting

Cutting through metal takes the right tools and expertise. Bluegrass Bit uses its specialized cutting tools and methods combined with industry-leading experts to offer precision metal cutting services. We cut through a variety of metals, such as exotic steel, stainless, inconel, zinc, and carbon-based alloys.

We make precise cuts in any environment, including those that require no sparks. Some of the jobs we tackle include cutting objects in nuclear reactors, airplane wings, ship rudders, compressor foundations, pipelines, steel turbine shafts, underwater conductors, and more.

The main benefits of our tools and methods are their safety and precision. We can use air- or water-cooled cutting systems to avoid contamination or dangerous sparks. Many of our methods will also avoid excess vibration and reduce noise.

We used our metal-cutting resources on a project for the Port of Los Angeles. The project required underwater cutting of metal berths before they could be removed by crane. We used a custom-built saw to complete the job at up to 28’ below the waterline safely and on schedule.

Core Drilling

Core Drilling is a precision demolition method used to achieve precise cuts in various demolition and repurposing projects. Bluegrass Bit can drill cores at depths up to 50’+ and any angle, with core diameters of up to 42”.

One of the main advantages of core drilling is the trueness of the cut. A core drill creates a perfectly round hole in a concrete structure with minimal disturbance. This hole can be used to access the structure for repairs or utilities. It is also used to feed in a diamond wire for saw cutting operations.

Bluegrass Bit used core drilling as part of its Brunswick Nuclear Plant project, where we drilled a 42” diameter hole through the three-foot thick condensate pit.

Concrete Shaving

Concrete shaving is another precision demolition process that involves removing a layer from the concrete surface. This is often necessary to remove contamination in nuclear, waste, and other facilities constructed from concrete.

Concrete shaving works by reducing the volume of concrete material on a wall, ceiling, or floor by shaving them to a predetermined depth. The contaminated materials are then carefully removed from the area, leaving it contamination free. The obvious advantage of this technique is that it allows facilities to remove contamination without a complete demolition and rebuild.

Bluegrass Bit used concrete shaving during the Rocky Flats Nuclear Weapons Plant decommission project. The initial phase required decontamination of all surfaces, which involved concrete shaving to .5” depths.

When Precision Demolition Is Used

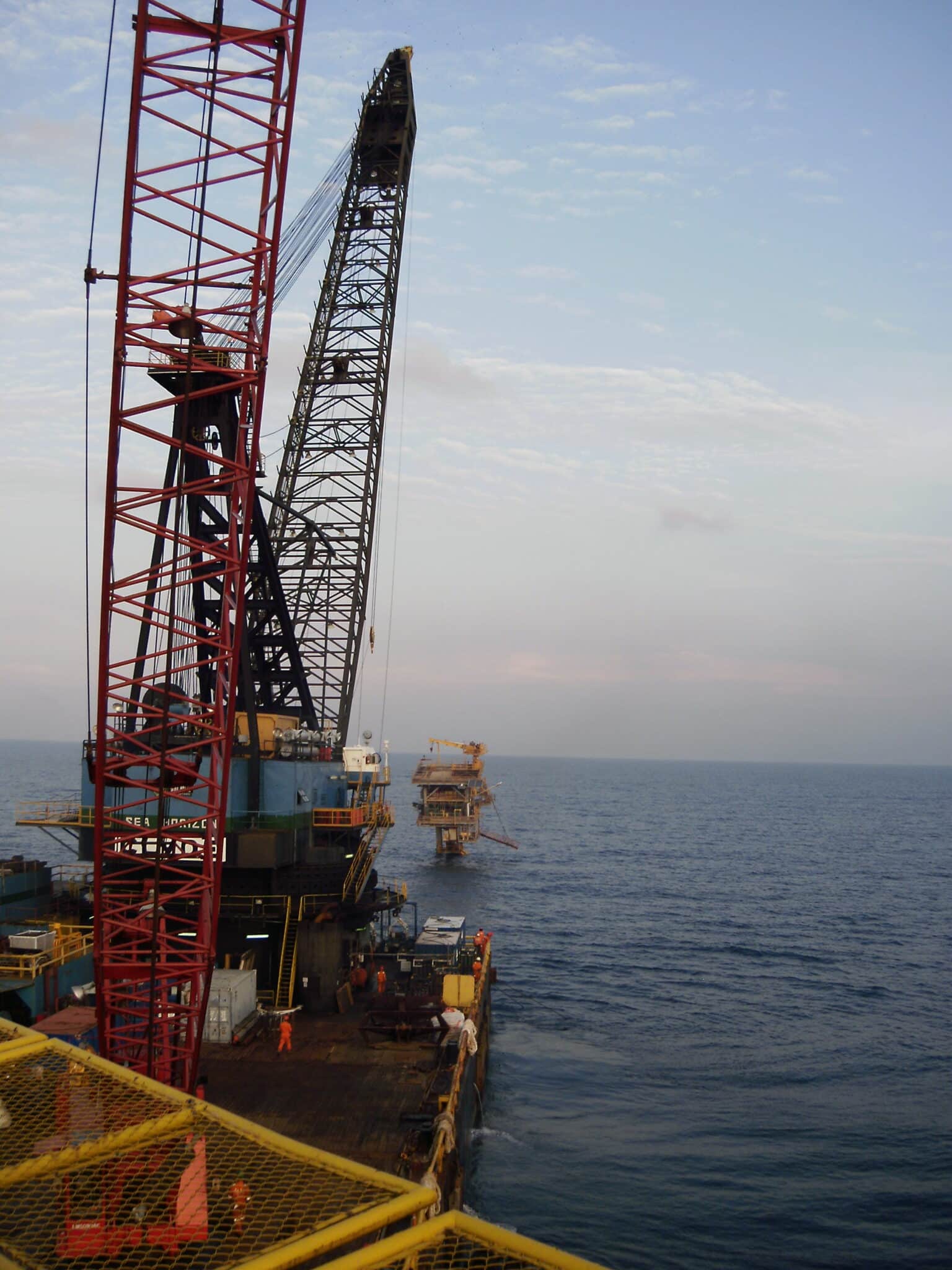

Precision demolition is a process that has come a long way over the past several decades. Bluegrass Bit uses its advanced equipment and technologies to assist clients in offshore, nuclear, heavy equipment, heavy metals, and heavy civil industries. Our methods work hundreds of feet in the air and in sub sea applications.

Contact Bluegrass Bit for Your Demolition Project

If you need a precision demolition project completed, contact us to find out how we can help. Bluegrass Bit is a global expert in precision demolition and decommissioning services. Founded in 1979, our company has received worldwide recognition for its pioneering use of diamond wire sawing as a non-explosive technique and method for cutting concrete and metal underwater.

Headquartered in Alabama, we also have offices in Louisiana, Texas, Wyoming and Florida. We support every one of our jobs with a highly skilled team of engineers, mechanics, project managers, machinists, and administrative staff. Contact us today to learn more about our services.