The process of offshore platform decommissioning encompasses more than physical dismantling; it represents a multifaceted challenge threaded with technical, environmental, and regulatory considerations. The complex nature of safely removing these colossal structures from their marine beds requires meticulous adherence to offshore decommissioning guidelines.

In this article, we’ll explore the critical details of this process, where every action is taken with the utmost concern for safety and minimal environmental impact. Continue reading below as we discuss the intricate logistics of offshore platform decommissioning and learn more about Bluegrass Bit’s integral role in the process.

Understanding the Offshore Decommissioning Process

As the demand for energy evolves and offshore resources are tapped to their full potential, operators face the inevitable task of retiring these giant marine sentinels. You might be wondering what offshore decommissioning entails and how it is transforming the landscape of oceanic oil and gas operations.

Offshore decommissioning is a finely orchestrated dance of engineering, environmental science, and maritime operations coordinating their expertise to retire offshore oil and gas installations. It’s a considerable undertaking which calls for meticulous planning and precise execution. This decommissioning procedure involves multiple steps, beginning with the decision to decommission through ensuring all environmental responsibilities are honored during the removal process.

Stages of Offshore Platform Decommissioning

The journey of an offshore platform from operational to decommissioned status is far from a single-step process. It involves a series of methodical steps:

Initial Assessment: In this early stage, engineers and experts appraise the offshore platform’s condition, potential environmental impacts, and the feasibility of various decommissioning strategies.

Regulatory Compliance: Securing the necessary permits and ensuring that the decommissioning process meets stringent regulations are essential for legal and environmental protection.

Preparation: This phase sees the platform prepared for removal and includes actions such as cleaning, well plugging and abandonment (P&A), and removing usable materials.

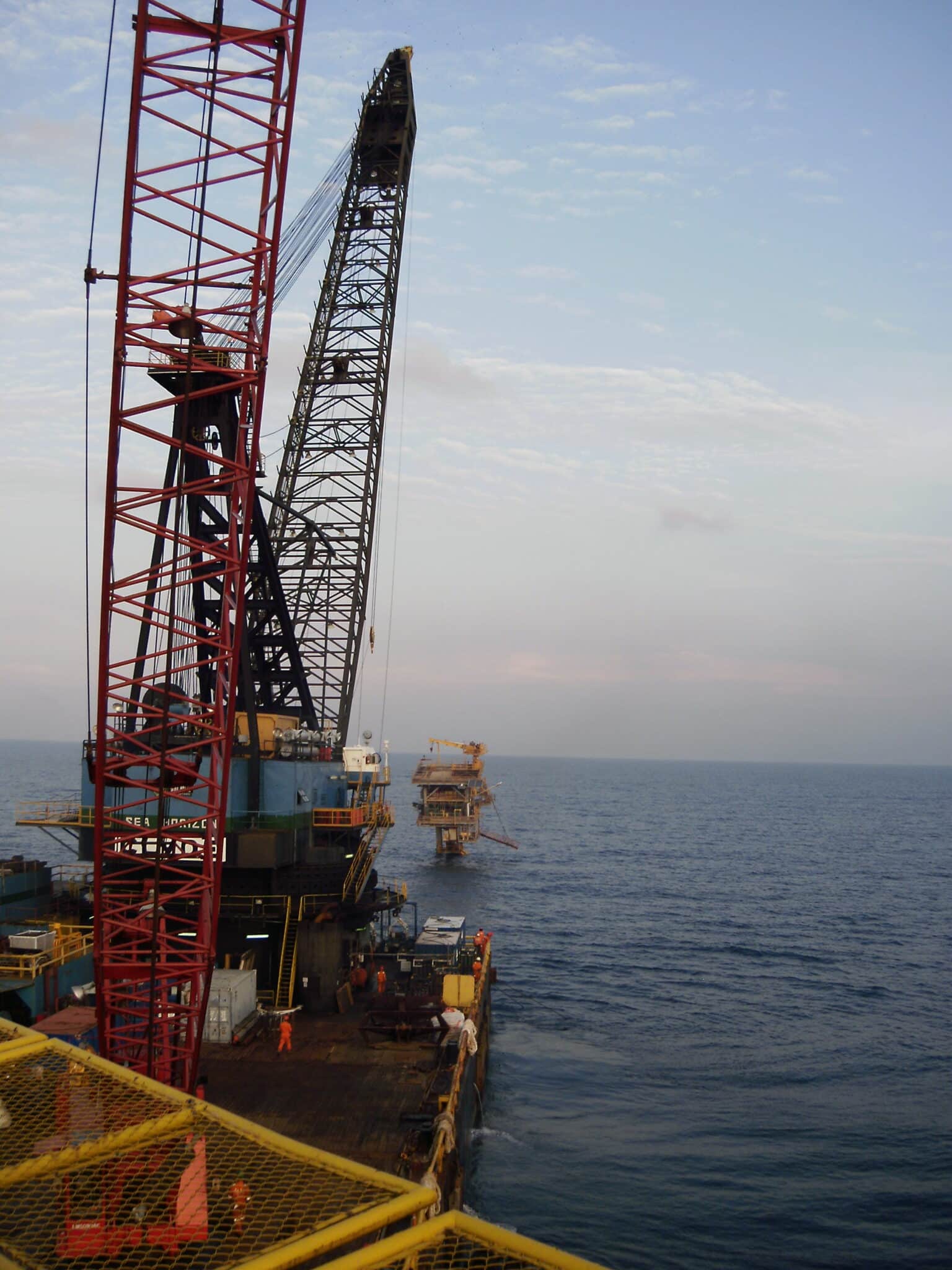

Physical Removal: The actual removal of the offshore platform can take numerous forms, from piecemeal dismantling using derrick barges or heavy lift vessels (HLVs) in deep water to removing the structure in larger sections. This step also involves decommissioning pipelines and power cables.

Site Clearance: Once the platform is removed, the ocean floor is cleared of debris and returned to as close to the natural state as regulations require.

Material Disposal and Reuse: Materials from the decommissioned platform are then either recycled, repurposed, or disposed of as per regulatory requirements.

Post-Removal Monitoring: To ensure the decommissioning process has been successfully completed, monitoring may be required for a pre-defined period following removal.

Key Challenges of Offshore Platform Decommissioning

The complexities involved in dismantling offshore platforms present challenges that require careful planning and strategic execution. Each player’s role in this delicate process is crucial in achieving the end goal: a safely decommissioned offshore platform with the minimum possible environmental footprint. Consequently, it is critical to understand that the challenges posed by offshore decommissioning projects are as varied as they are demanding:

Environmental Stewardship

Paramount to the decommissioning process is the environmental impact assessment (EIA). This evaluation is intended to safeguard marine ecosystems and ascertain how to minimize the footprint of decommissioning activities. See details of the EIA process below.

Regulatory Compliance

With decommissioning regulations being as rigorous as the structures to which they are applied, compliance is more than a legal formality; it’s an operational blueprint. The international and local decommissioning regulations dictate the process from inception to completion, ensuring safety and environmental protection.

Technical Complexities

The intricate architecture of offshore platforms implies that technical hurdles are inevitable. The unpredictable nature of the marine environment and the need for specialized equipment further complicate the decommissioning process.

Logistical Coordination

The coordination of multiple vessels, crews, and equipment is an operational ballet that demands precise program management. Logistical complexities escalate costs and extend timelines, underscoring the need for meticulous planning.

Risk Management

Informed decision-making is the bulwark against unforeseen circumstances. Risk mitigation strategies must be in place to address potential hazards ranging from structural integrity to adverse weather impacts during the offshore decommissioning endeavor.

Environmental Impact Assessment During Decommissioning

Offshore decommissioning not only focuses on the physical dismantling of structures but also significantly hinges on conducting thorough environmental impact assessments (EIAs). An EIA is integral to the decommissioning process, ascertaining that all operations meet the highest environmental standards and showcasing a commitment to ecological accountability.

These rigorous assessments involve detailed analysis of the potential environmental effects caused by offshore decommissioning activities. Through EIAs, your efforts to minimize the ecological footprint are not just documented but scrutinized to align with the best environmental practices.

Assessment of Marine Ecosystems: A thorough study of the marine environment around the decommissioning site is conducted to understand the potential impacts on local flora and fauna.

Evaluation of Pollution Risks: EIAs thoroughly evaluate the risk of pollution, from oil spills to the dispersal of hazardous material, ensuring such risks are mitigated to the greatest extent possible.

Analysis of Decommissioning Methods: The EIA scrutinizes the selected decommissioning techniques, considering their environmental compatibility and sustainability, thereby guiding the selection of environmentally preferable options.

Public Consultation: Incorporating inputs from stakeholders and the public, EIAs foster transparency and ensure that community concerns regarding environmental and fisheries impacts are considered.

Development of Mitigation Strategies: By identifying environmental sensitivities, EIAs lead to the formation of explicit mitigation strategies aimed at preserving marine life and habitats.

Legal and Regulatory Framework Governing Offshore Decommissioning

Every jurisdiction where offshore platforms operate has decommissioning regulations in place. These are designed to ensure the safe cessation of operations and minimum environmental impact.

As you begin the decommissioning process, it is imperative to have a complete understanding of the local regulations applicable to your project. Navigating these rules requires a thorough risk assessment, careful planning, and robust execution strategies, all of which align with the legal requirements specific to the platform’s location.

Furthermore, international guidelines further govern the offshore decommissioning process. Organizations such as the International Maritime Organization (IMO) provide frameworks and standards that transcend national boundaries, promoting safety and environmental conservation on a global scale.

Compliance with international standards demonstrates a commitment to sustainability and responsible stewardship of marine environments. By adhering to these offshore decommissioning guidelines, the final chapter of the offshore platform’s life is concluded with integrity.

Strategic Approaches to Offshore Platform Decommissioning

Crucial to selecting a decommissioning strategy is a comprehensive evaluation based on the unique characteristics of each offshore platform. Factors such as engineering design, geographical location, and ecological sensitivities profoundly influence the decision-making process. In addition, stringent adherence to regional and international regulatory compliance plays a formidable role in dictating the feasible course of action.

Here are some strategic approaches to consider:

Complete Removal: This traditional method involves the full dismantling and removal of offshore platforms, allowing the seabed to be restored to its natural state, albeit often at higher costs and with significant logistical demands.

Partial Removal: Under certain conditions and in compliance with regulations, it may be more advantageous to remove only parts of the platform that can pose navigational or environmental risks, leaving the remaining structure to integrate with the marine habitat.

Toppling On-Site: Occasionally, it is possible to topple the platform onto the ocean floor to create artificial reefs, promoting marine life, a strategy that hinges on a detailed environmental impact assessment.

Repurposing: Innovative solutions involve reassigning decommissioned platforms for alternative uses, such as research facilities, renewable energy production, or even recreational destinations, thereby extending their service life in an environmentally friendly manner.

Single Lift Operations: Technological advancements have led to the development of heavy lift vessels (HLVs) capable of removing large offshore structures in a single lift—this approach often proves to be safer, quicker, and, in some cases, more cost-effective.

Bluegrass Bit’s Commitment to Safety and Expertise in Decommissioning Services

At Bluegrass Bit, we understand the intricacies involved in planning and executing offshore decommissioning projects. Our custom-built saws are designed to withstand the rigors of the marine environment and can be deployed underwater using divers and/or ROVs. With unparalleled experience in the industry, we’re equipped us to successfully complete the most demanding metal and concrete cutting tasks topside and underwater.

Our specialized expertise in diamond wire sawing provides cutting solutions that meet environmental regulatory standards. Our teams are committed to safety, experienced, certified, and credentialed to operate offshore (including TWIC, BOSIET, HUET / SWET, and Safe Gulf certified). Bluegrass Bit’s cutting solutions contribute to environmental compliance and operational safety on every decommissioning project we undertake.

Contact Bluegrass Bit today to discover how our tailored concrete and metal cutting solutions can streamline your project, reduce risks, and enhance efficiency. Our team of experts is ready to assess your project specifications and offer a cutting strategy that aligns with each project’s unique demands and objectives.