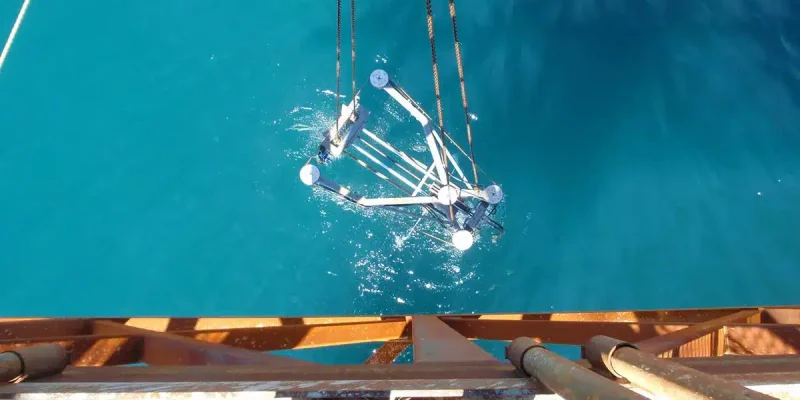

All Bluegrass underwater saws can be fitted with a hydraulic clamping system, with a diver clamping system, and/or with ROV attachments and connections (a Hot Stab Panel). Designing and fabricating our own saws means they can be serviced by our technicians in the field, and specialty parts can be immediately fabricated. In addition to reliable equipment, the continuous loop diamond wire we use has a proven track record which means predictable outcomes for our customers.

Understanding Underwater Saws

Designed for zero-visibility waters:

- Wide berth on hydraulic clamps means divers can successfully ring structure faster.

- Large berth allows saw to loosely ring structure topside, prior to deployment, then clamp into place at desired depth.

- Hydraulic clamp is self-centering. If ringed off-center, saw self-adjusts to center for clamping.

- Operate at depths to 4,000 ft

Our Unique Advantage

- No Middle Man – in-house R&D lowers your costs

- Attention to Detail – exact cuts and fully prepped equipment

- Raw Resources – 100,000+ feet of diamond wire and 60+ saws

- Specialized Saws – plunge, underwater, land, and custom saws

- Pioneer Experience – we started diamond wire demolition