When you step onto a demolition site, you’re entering a world of meticulous operation and precision, laced with distinct hazards. As a result, adherence to heavy metal cutting safety protocols and demolition safety guidelines is not just about compliance—it’s about protecting your workforce.

Recognizing the substantial risks involved in heavy metal cutting and demolition, you understand the need to integrate workplace safety guidelines. Below, we’ll discuss the various risks involved in heavy metal cutting and demolition, how to keep your crew safe, and best practices to help inform your safety management procedures.

Continue reading below to learn more about how to fortify your approach to workplace safety and why experienced experts at Bluegrass Bit Company can help ensure operational safety and efficiency in your next project.

Understanding the Risks in Heavy Metal Cutting and Demolition

As you navigate the complexities of heavy metalwork, recognizing the myriad risks involved is the first step toward implementing safe practices in heavy metalwork. Not only do these practices ensure the safety and well-being of your employees, they also contribute to maintaining industrial demolition compliance.

Below, we’ll explore some common hazards in heavy metal cutting and demolition work environments that underline the vital importance of adhering to workplace safety measures.

Identifying Workplace Hazards

Every task in the world of heavy metalwork comes with its own set of dangers. Understanding each of these risks provides the knowledge necessary for taking proactive steps in risk mitigation and ensuring a safer workplace.

- Exposure to harmful dust particles, including silica, can lead to serious respiratory issues.

- High noise levels can cause long-term hearing damage.

- Vibrations from power tools may lead to hand-arm vibration syndrome (HAVS).

- Potential for falling objects or structural failures that present a risk of physical injury.

Furthermore, invisible threats like hazardous materials hidden in the walls—such as lead, asbestos, or silica—require specialized handling and are crucial for maintaining industry standards of demolition safety. The possibility of encountering materials with unpredictable strengths or weaknesses, including post-tensioned concrete, further underscores the need for vigilance in safe demolition practices.

Essential Safety Gear for Heavy Metal Cutting and Demolition

When you’re tasked with the challenging work of heavy metal cutting and demolition, having the right metal cutting safety gear isn’t just recommended—it’s imperative. The gear worn by personnel includes protective elements designed to shield you from the various hazards presented by these high-risk activities.

Let’s examine the personal protective equipment critical to ensuring on-the-job safety at demolition and metal cutting job sites.

Personal Protective Equipment (PPE)

Your first line of defense against the rigors of metal cutting and demolition is a robust set of PPE. This essential metal cutting safety gear serves well to ward off the inherent dangers of the trade, ensuring that you remain secure and sound throughout the workday.

- Helmets: Guard your head from impacts and falling debris with industrial-grade safety helmets.

- Eye Protection: Shield your eyes from sparks and particulate matter with high-quality goggles or face shields.

- Gloves: Defend your hands against cuts, abrasions, and vibrations with gloves engineered for heavy-duty use.

- Respiratory Masks: Preserve your lung health by filtering out harmful airborne particles with effective respiratory masks.

- Hearing Protection: Maintain your hearing integrity in high-decibel environments with earplugs or earmuffs.

Specialized Equipment

While PPE is crucial, there is also specialized equipment which augments your safety by addressing the specific challenges of metal cutting and demolition. Invest in these metal cutting equipment safety advancements to ensure your personal welfare as well as the efficiency and longevity of your operations.

- Sound dampening tools to reduce the risk of hearing damage in environments with constant high noise levels.

- Automated machinery allows for remote operation, thereby minimizing the need for direct human interaction with potentially hazardous tasks.

- Vibration-reducing tools that help prevent HAVS and other related injuries from prolonged equipment use.

- Containment systems for the management and control of dust, debris, and other airborne particulates.

- Chuck guards and workpiece guards to protect against the rotation hazards.

Best Practices for Safe Operation of Cutting Tools and Demolition Equipment

In the demanding world of industrial demolition and metal cutting, adhering to best practices is not only essential for efficiency but critical for your safety and that of your colleagues. Embracing these practices helps create a safe workspace where you can focus on the task at hand, confident in the knowledge you are well-trained, your equipment is reliable, and you are prepared for emergencies.

Training and Certification

Ensuring that you and your team are fully trained and certified is the cornerstone of safe demolition practices. Comprehensive training programs for metal cutting equip workers with the knowledge necessary to handle equipment safely and respond to potential hazards with competence:

- Enroll in accredited courses that offer hands-on experience and learning materials tailored for industrial metal cutting.

- Obtain certifications that validate your proficiency in operating specific types of demolition equipment.

- Stay informed about evolving techniques and safety standards to continually enhance your skill set.

Regular Maintenance and Safety Inspections

Proactive and regular equipment maintenance is indispensable in mitigating the risks associated with equipment failure. Implementing systematic demolition equipment safety inspections leads to an environment where potential issues can be identified and rectified before they escalate:

- Conduct daily checks to ensure that cutting tools and demolition machinery are in proper working order.

- Adhere to a routine maintenance schedule, following manufacturers’ guidelines to extend the service life of your equipment.

- Schedule in-depth inspections by qualified professionals periodically to certify that all components meet safety standards.

Emergency Response Preparedness

No matter the scale of the project, being prepared for an emergency is paramount. A robust emergency response plan will not only contain the situation but also minimize harm to personnel and property.

Safety Management in Demolition Projects

Demolition work is inherently risky, but with the right approach to safety management, risks can be substantially reduced. Each step you take toward enhanced safety measures not only serves to protect your team but also ensures compliance with strict demolition regulations.

Risk Assessment and Planning

Before the first metal cutting diamond wire saw is switched on, it is paramount that you conduct a comprehensive risk assessment. This involves identifying potential hazards inherent to your specific project and devising strategic plans to mitigate them:

- Analyze previous incident reports and statistics to inform your risk management strategy.

- Thoroughly examine the structural integrity of buildings prior to demolition to anticipate any challenges.

- Ensure that a detailed demolition plan is in place, outlining all safety measures and protocols to be followed.

- Engage with experts in demolition safety protocols to review and refine your plans for risk management in demolition.

Controlled Demolition Techniques

Controlled demolition allows for the systematic deconstruction of structures in urban settings, ensuring stability and minimizing unforeseen incidents. Techniques vary based on many variables including the configuration of the structure and urban planning considerations:

- Consider the use of explosives for large-scale demolitions performed by licensed professionals.

- Utilize dismantling methods where structural elements are carefully taken apart in a predetermined sequence.

- Implement mechanical demolition for non-explosive deconstruction, using specialized equipment under strict safety measures.

- Incorporate precision felling, where structures are meticulously cut and guided to fall in a specific manner.

Safe Handling and Disposal of Debris

Post-demolition, dealing with the aftermath is as critical as the teardown itself. By applying rigorous demolition safety protocols, engaging in proactive risk management, and ensuring safe debris disposal, you underpin the fabric of a successful and secure demolition operation.

- Sort materials for recycling or repurposing to reduce waste and adhere to sustainable practices.

- Dispose of hazardous materials according to federal and state guidelines to prevent environmental contamination.

- Implement safe debris disposal procedures, utilizing proper PPE and machinery to handle and transport debris.

- Conduct continuous site clean-up to maintain an organized, hazard-free workspace throughout the demolition process.

Regulatory Compliance and Industry Standards

Navigating the labyrinth of regulations in heavy metal cutting and demolition is crucial for your business to thrive. Complying with these mandates is not only a legal requirement but also a testament to your commitment to safeguarding your employees and operations.

Let’s examine the critical role of the Occupational Safety and Health Administration (OSHA) and explore the extensive ladder of international standards aimed at refining the safety processes within your industry.

OSHA and Other Regulations

The Occupational Safety and Health Administration (OSHA) sets the benchmark for OSHA compliance in metal cutting. Their standards are designed to mitigate risks involved in the metal cutting processes, including those related to noise levels, air quality, and Personal Protective Equipment (PPE). To avoid non-compliance penalties and reinforce workplace safety, you should familiarize yourself with OSHA’s guidelines:

- Adopt and enforce the use of PPE as per OSHA standards, ensuring that all employees are adequately protected.

- Maintain permissible noise exposure levels and provide hearing protection when necessary.

- Implement controls for air contaminants, particularly in operations where metal cutting can release toxic fumes.

Global Standards

While OSHA is a predominant regulatory body in the United States, international demolition safety standards must also be taken into consideration, especially for businesses operating on a global scale. These international benchmarks ensure that safety transcends borders and that best practices are uniformly adopted:

- Align with the International Standards Organization (ISO) criteria for demolition and metal cutting operations.

- Adhere to European Union directives and regulations that might apply to specific equipment or safety methods.

- Understand and comply with local safety standards in countries where you operate, as these can vary significantly.

Bluegrass Bit Company’s Commitment to Safety and Efficiency

The complexities of heavy metal cutting and demolition require a steadfast commitment to maintaining a safe working environment. By integrating the best practices discussed and perpetually aligning with regulatory standards, you reinforce the shield that safeguards your employees and your business’s longevity. Remember, the investment you make today in safety protocols and training is the groundwork for a protected, efficient, and compliant industrial landscape tomorrow.

Are you seeking unparalleled expertise in demolition and decommissioning services from a company that also values safety?

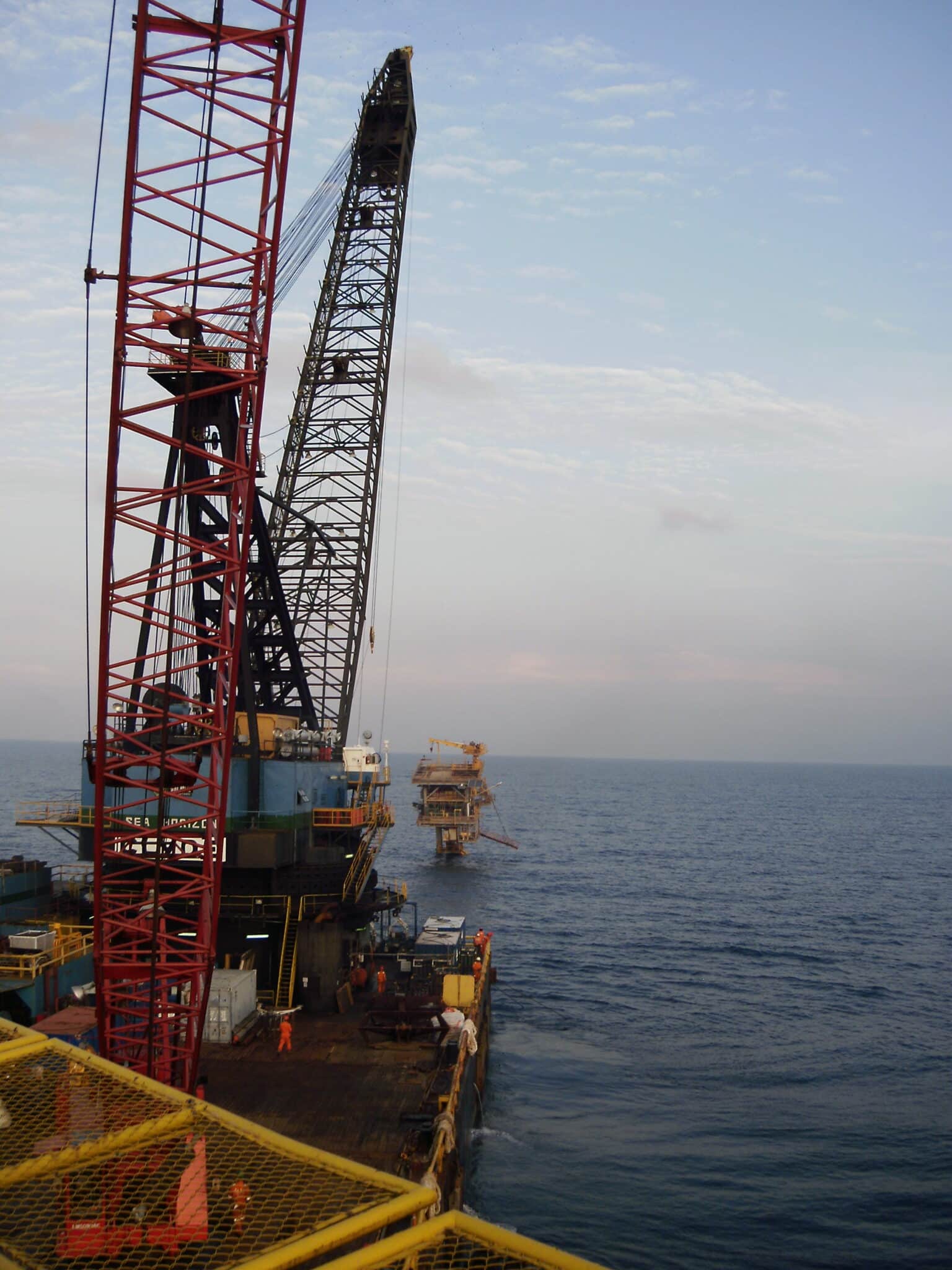

At Bluegrass Bit Company, we understand the complexities of your projects and are ready to deliver customized solutions tailored to your unique needs. Our innovative diamond wire cutting technology, coupled with a robust commitment to safety and efficiency, has made us an industry leader since 1979. Whether tackling heavy industrial, civil, nuclear, or offshore challenges, our team of skilled professionals is equipped to handle each project with precision and care.

Experience the difference with Bluegrass Bit Company’s specialized approach. Contact us today to discover how our advanced cutting technologies and customized solutions can elevate your next project and ensure operational safety and efficiency at every phase.