The industrial demolition landscape is transforming, with new technology at the forefront of groundbreaking changes. With the emergence of advanced demolition equipment redefining efficiency and precision, understanding why industry professionals are quickly adopting these cutting-edge tools is crucial.

In this article, we’ll discuss the evolution of industrial demolition techniques and provide a complete overview of how innovative demolition technology is paving the way for future projects of all scales. Keep reading to learn more about the latest industrial demolition technologies and discover how Bluegrass Bit Company and our groundbreaking solutions can elevate your next project to new heights of safety and efficiency.

The Evolution of Industrial Demolition Techniques

The industrial demolition industry has undergone significant transformation over the years. The early days of demolition technology appear rudimentary by today’s standards, yet they set a cornerstone for the modern practices currently revolutionizing industrial demolition.

Manual Labor and Simple Tools: The genesis of demolition can be traced to the brute force of sledgehammers, pickaxes, and manual labor. These methods, although labor-intensive, paved the way for a burgeoning industry.

Powder-based Demolition: Black powder, followed by dynamite, signified a leap in efficiency and potency in bringing down structures, showcasing demolition technology in its infancy.

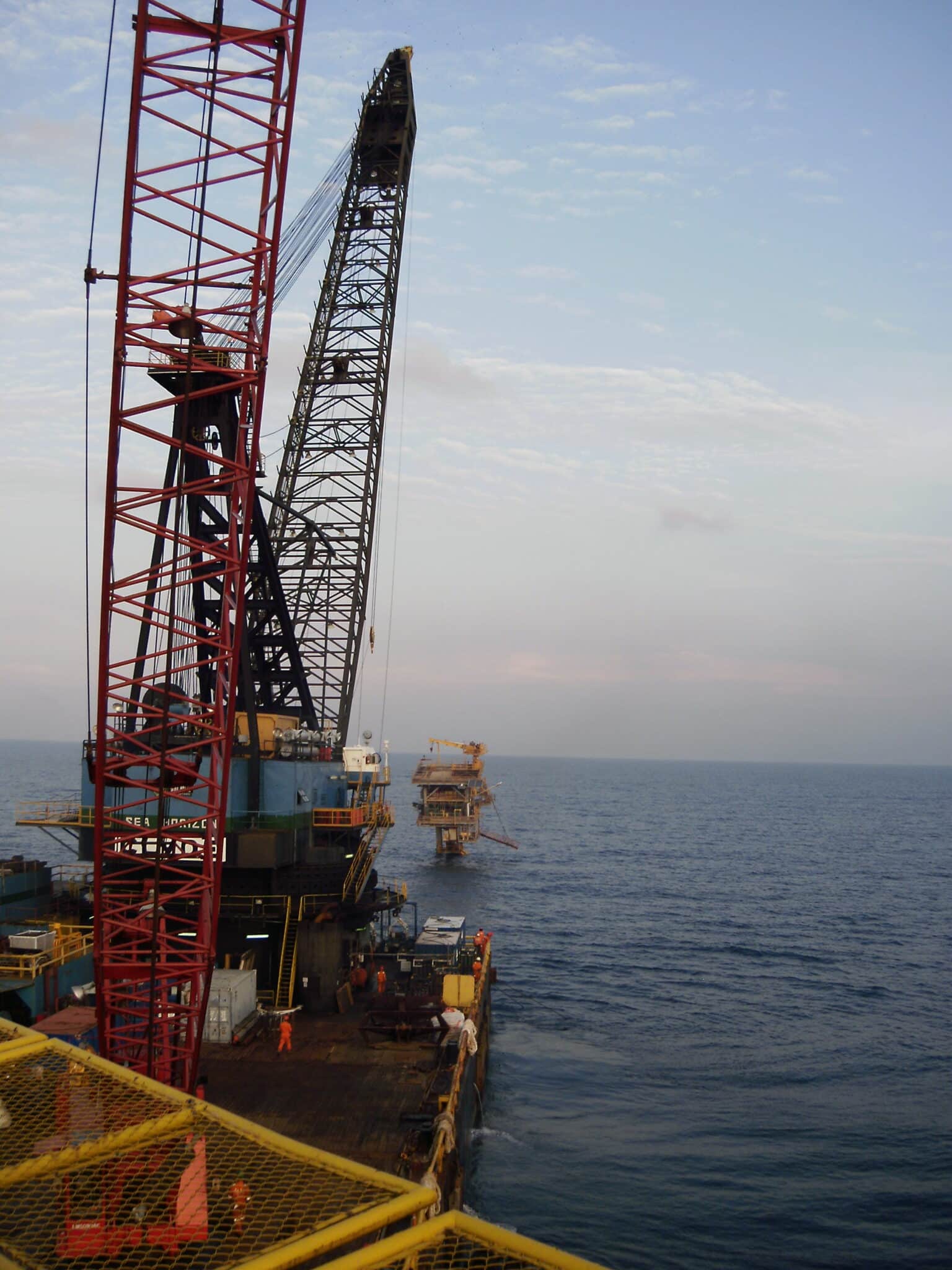

The Crane and Wrecking Ball: Symbolic of urban renewal in the 20th century, the wrecking ball became a hallmark of demolition, inspiring awe with its sheer power and simplicity.

Thermal Cutting Techniques: The introduction of torches capable of cutting through steel allowed for more refined deconstruction of buildings, marking an important advancement in demolition technology.

These milestones represent the progression towards the sophisticated methods now synonymous with industrial demolition. From cumbersome and unsafe practices, we now experience a realm where advanced demolition equipment ushers unparalleled precision, speed, and safety.

Recognition of Environmental Impact: In recent decades, a growing awareness of demolition’s environmental footprint has prompted a shift towards greener practices within the industry.

Integration of Advanced Machinery: Hydraulic excavators, concrete crushers, and noise barriers are a testament to the ingenuity invested in modern industrial demolition.

Regulatory and Safety Advances: A shift in focus to safety led to stricter regulations and the development of precision demolition technology, minimizing risk while maximizing efficiency.

Cutting-Edge Technologies Transforming Industrial Demolition

Advanced demolition equipment and innovative strategies are reshaping what it means to bring down structures, making industrial demolition a high-tech field that balances precision with responsibility. Integrating modern technology empowers demolition contractors to work smarter and supports the industry’s commitment to environmental sustainability and worker safety.

Let’s take a look at some of the new advancements reshaping the demolition industry:

Robotic Demolition

The advent of robotic demolition has signified a groundbreaking shift in demolition technology. These highly specialized machines operate in hazardous conditions where human presence is risky. Robotic demolition brings unparalleled precision, often required in tight spaces or close proximity to structures that must be preserved. Equipped with various attachments, demolition robots can crunch, crush, and cut through concrete and steel with pinpoint accuracy.

3D Scanning

Integrating 3D scanning into demolition planning transforms how projects are visualized and executed. By creating detailed models of structures, demolition experts can now simulate various scenarios and devise strategies that maximize efficiency while curbing potential risks. This level of detail facilitates meticulous project management, ensuring every cut and demolition sequence is optimally planned, and resources are allocated effectively.

Controlled Demolition Techniques

Controlled demolition techniques are the epitome of precision in the demolition field. Procedures like implosion and pre-weakening methods necessitate extensive planning and the deployment of advanced demolition equipment. High-reach excavators and explosives are orchestrated to bring down structures within specified parameters, minimizing the impact on surrounding environments and ensuring the safety of both the demolition team and the public.

Drones

Drones, or unmanned aerial vehicles (UAVs), are increasingly prominent in modern demolition techniques. Their ability to soar above a demolition site provides an essential vantage point for project managers and engineers. Drones contribute not only to the planning phase with aerial surveys but also play a crucial role in monitoring safety during the execution of demolition work, offering real-time data and perspectives that are invaluable for decision-making.

Advancements in Safety and Environmental Compliance

The significance of maintaining stringent safety and environmental protocols cannot be overstated when working with modern demolition techniques. With the advancement of demolition technology, innovative measures have been introduced to safeguard the well-being of workers and uphold eco-friendly practices. In this section, we explore the latest developments in safety equipment and the burgeoning sustainable practices shaping the current landscape of industrial demolition.

Innovative Safety Equipment and Protocols

Adopting new safety equipment and protocols is crucial in an industry where risk is ever-present. Let’s look at how cutting-edge gear and rigorous training programs minimize hazards on the demolition site.

- Enhanced personal protective gear designed to resist impact, noise, and airborne particulates, ensuring worker safety amidst the chaos of demolition.

- Advanced training programs that equip demolition professionals with the expertise to navigate complex industrial demolition environments through simulation and real-life scenarios.

- Compliance with updated safety protocols integrating the latest technology to accurately assess risks and implement control measures.

Sustainable Demolition Practices

The industrial demolition sector is increasingly leaning towards sustainable practices, demonstrating its commitment to environmental stewardship. Here’s how demolition teams are implementing greener methods to reduce their ecological footprint:

- Recycling of materials extracted from demolition sites reduces the demand for new raw materials and decreases landfill waste.

- Waste management strategies that prioritize sorting, repurposing, and responsible disposal to minimize environmental impact.

- The use of precision techniques throughout the demolition process ensures only the necessary structures are affected, thus conserving resources and energy.

The Future of Demolition with Bluegrass Bit Company

Though the exact trajectory of industrial demolition technology remains uncertain, what is clear is that these advancements will redefine what is possible, ensuring that future structures can be dismantled and decommissioned with thoughtfulness and precision, respecting both human safety and environmental sustainability. By embracing cutting-edge equipment and forward-thinking practices, the demolition industry stands at the forefront of a new era where technology sets new standards and redefines possibilities.

Are you looking for a partner to revolutionize your industrial demolition and decommissioning projects? Look no further than Bluegrass Bit Company, the leader in providing innovative, efficient, and safe demolition solutions.

At Bluegrass Bit Company, we pride ourselves on being a benchmark of excellence, and our commitment to safety and precision solutions makes us the first choice for businesses across various industries. Our pioneering expertise in specialized diamond wire-sawing technologies ensures precision on every project, safeguarding your investment and prioritizing safety while managing environmental considerations.

With Bluegrass Bit Company, you’re not just choosing a service provider; you’re partnering with a pioneer in the demolition industry. Contact us today to see how our cutting-edge techniques and seasoned expertise can empower your next demolition project.