There are many different approaches to cutting and removing concrete. Ring saws are one option because they are easy to handle, but they also have many limitations. If you need thicker materials cut and want something done with precision, a diamond wire saw is a better option.

There are many different approaches to cutting and removing concrete. Ring saws are one option because they are easy to handle, but they also have many limitations. If you need thicker materials cut and want something done with precision, a diamond wire saw is a better option.

Diamond wire saws are used to remove reinforced or large concrete structures by segmenting. Wire saws can cut through nearly any material because diamonds are among the hardest materials in the world.

In short, a diamond wire saw is a saw which rotates loops of wire cable onto which are threaded metal beads crusted with diamond chips. The entirety of the cable and the beads is then protected from corrosion by an elastomeric compound covering. The cable is made of multiple strands of high-tensile steel wire.

How Do Diamond Wire Saws Work?

If you’ve ever used a bandsaw or reciprocating saw, a wire saw operates using the same basic principles. The diamond wire is arranged around the material that requires cutting. It can also be threaded through a core hole. Then, the wire saw is rotated at speed, using the abrasion of the diamonds on the wires to cut through the concrete or other materials.

Diamond wire cutting produces a significant amount of heat, which means cooling is essential. Many diamond wire saws use “wet cutting,” meaning there is a flow of water to provide cooling.

What Are the Benefits of Using Diamond Wire Saws?

Using the strength of diamonds to cut through thick, dense, and hard materials like concrete and metal is incredibly useful. Here are some of the main benefits of diamond wire saws.

They Can Cut Any Size

Diamond wire saws have the ability to cut through any thickness or size of concrete and steel. The power and precision of these tools mean that they can tackle major projects like columns, beams, sections of bridges, dams, and other structures. Once cut, the sides of the material are smooth, making them easier and safer for workers to handle.

They Are Incredibly Accurate

Diamond wire sawing is incredibly accurate. Trained professionals can deliver precise results even in the most extreme conditions, such as underwater or in tight spaces. Diamond wire saws are also very effective at cutting awkward corners and odd shapes. The flexibility of the wire allows technicians to complete work to precise specifications.

They Are Highly Efficient

Time is money when it comes to construction and demolition projects. Diamond wire cutting does the job with incredible accuracy and speed. Other cutting techniques don’t come close to measuring up. Because it is so efficient, there are less wasted materials at the end of the process and fewer work hours required to get the job done correctly.

They Are a Safe Option

Removing concrete and steel isn’t a safe activity by any means, but using diamond wire sawing is one of the safest options for workers. It’s fumeless, less vibrational, and quieter than other sawing options. With that said, only trained professionals should use diamond wire saws.

What Are the Different Applications for Diamond Wire Saws?

Diamond wire saws were initially used to cut stones in quarries. Over the years, their uses have expanded substantially. A diamond wire saw can cut through concrete (including reinforced concrete), steel, stone, granite, and brick. Some of the most common applications for wire sawing include the following.

- Precision concrete demolition projects

- Cutting through concrete structures, such as dams, bridges, columns, beams, and factory floors

- Dismantling nuclear power plants

- Cutting through openings with limited access

- Angular cuts on horizontal and vertical structures

- Precision cuts on restricted, sensitive, or confined areas

- Cutting through heavy rebar or embedded steel

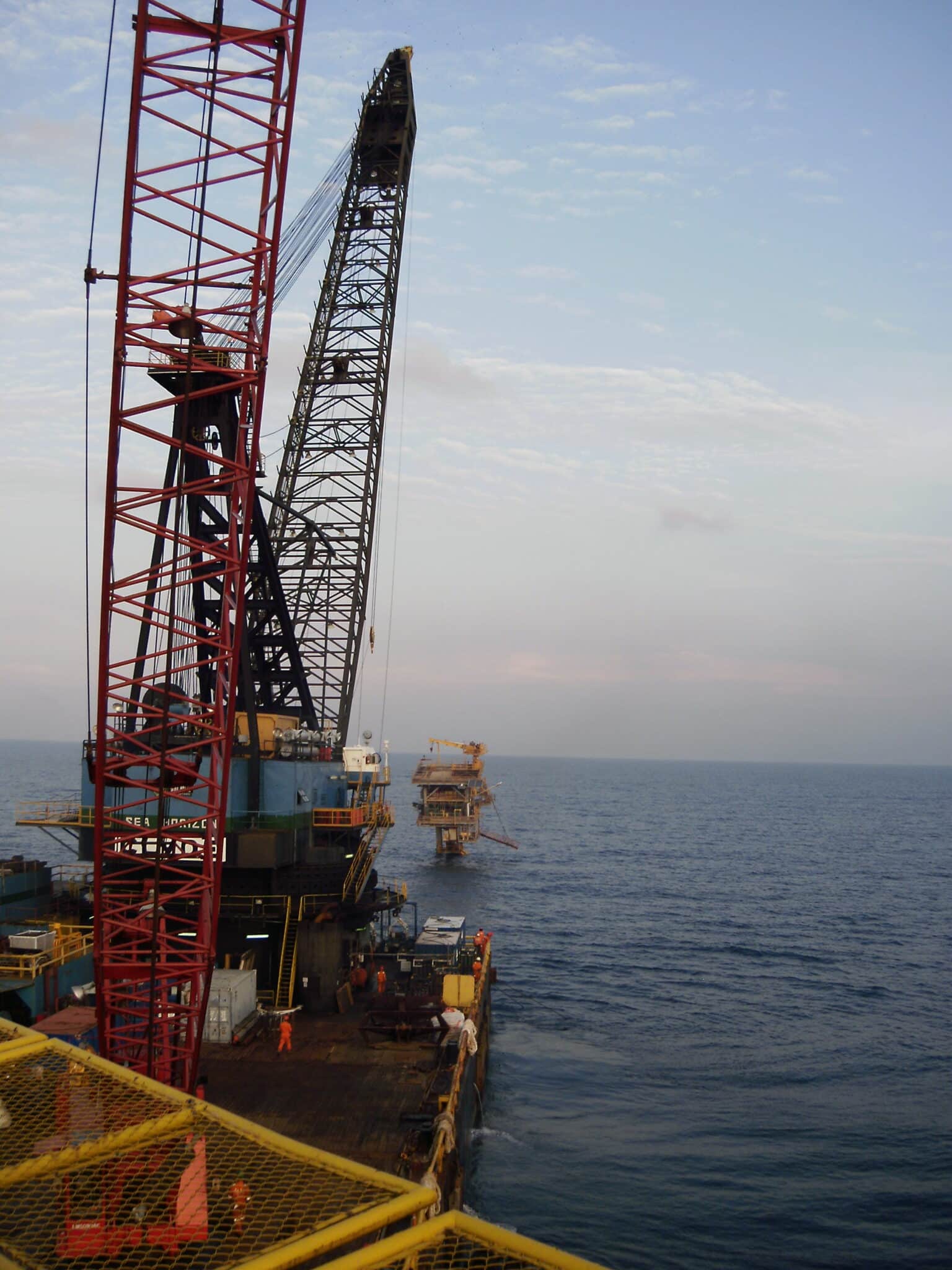

- Subsea cutting of, pipelines, and other underwater concrete or metal structures

Just a Few of Our Diamond Wire Sawing Projects

Bluegrass Bit Company has worked on many diamond wire sawing projects. Here are just a few real-world solutions showing how our experts can cut anything.

- Gross Reservoir Dam Expansion — Bluegrass Bit has played an integral part in Denver Water’s Gross Reservoir expansion. In Project Phase 1, we removed the dam’s ogee crest by inserting diamond wire saws into core holes to cut blocks for removal.

- Lake Matthews Water Intake Structure Modifications — We used diamond wire saws to remove a 30’ diameter concrete water intake structure in sections to modify this water intake area of the Colorado River.

- Port of Los Angeles — We removed a 14.5’ diameter concrete and metal sheet pile cell at the Port of Los Angeles. Using a specially designed 15’ underwater diamond wire saw, the material was cut into pieces and removed by a crane.

- NASA Concrete Silo Dismantling — We assisted NASA in removing existing concrete silos built for the space shuttle booster rocket to make way for other projects. Using diamond wire saw technology, we cut the concrete silos into segments for removal ahead of schedule.

Worldwide Diamond Wire Sawing Services

Concrete cutting is one of Bluegrass Bit Company’s foundational services. We have revolutionized the field of precision concrete demolition and construction using our custom-built diamond wire technology. We became the first demolition company to use diamond wire saws for controlled demolition in the late 1970s.

Our concrete and metal cutting services are the safest and most precise in the industry. Our saws can cut a wide variety of materials under the most extreme conditions. We work on land, on elevated platforms, and deploy wire saws underwater at locations across the globe. Contact us today for more information about our diamond wire sawing services.