If your facility has concrete in the wrong place or needs to make some changes for another reason, what are your options? Blowing it up is probably one, but that route has many downsides, including being dangerous and destructive to surrounding structures.

The best solution is concrete cutting, which is safer and more controlled. Here is what you need to know about concrete cutting, how it’s used, and the different methods for precisely removing concrete during your project.

What Is Concrete Cutting?

Concrete cutting is a controlled process that modifies or removes concrete. Because concrete has a high compressive strength relative to many other construction materials, it requires a unique approach when you need to change its structure. If you need to make any repairs or improvements to your facility, and concrete is involved, you must cut the concrete to get it done.

Types of Concrete Cutting Methods

When you know you need to modify your concrete, what’s the proper way to do it? Depending on your circumstances and goals, there are several different types of concrete cutting methods.

Wall Sawing

Wall sawing refers to making a cut into an existing concrete wall. To accomplish this, a concrete cutter will use a large diamond blade or a diamond wire saw that can cut completely through the wall. The saw will have an attachment allowing it to be guided along an established line or track in the wall.

Slab Sawing

Similar to wall sawing, slab sawing involves cutting horizontal pieces of a concrete floor, road, bridge, or anything else that is flat. One operator runs the slab saw from behind to guide it along the surface.

Core Drilling

Core drilling involves cutting a round hole into a specific area of the concrete. This is commonly used to facilitate repairs or add in a variety of infrastructure components such as wiring, plumbing, or ventilation. The holes vary in depth and diameter, depending on their intended purpose.

Wire Sawing

Wire sawing is a particular concrete cutting tool that requires experience and skill to set up and operate, but these saws are the most accurate concrete cutters available. A diamond wire saw is made of a main wheel that is driven by a hydraulic or electric motor, which steadily pulls the diamond wire along the cut path. The diamond beads use friction to cut through any material, from concrete to titanium.

Why Concrete Cutting Is Used

Concrete cutting is common in construction and demolition projects where the primary material used is reinforced concrete, cemented concrete blocks, concrete bricks, stones, and other hard-to-cut items. A variety of projects will use concrete cutting, such as bridges and overpasses, dams, wharves and piers, sewage treatment plants, chemical plants, and nuclear power plants.

Benefits of Concrete Cutting

Concrete cutting offers numerous benefits over methods like explosive demolition.

Less Intrusive

When you blow something up, there’s a chance you might damage more than you intended. Even the most skilled explosive expert can’t make guarantees, while concrete cutting only targets the areas you want to be altered. Thus, it is much less invasive to your structure.

Quieter

Explosives are noisy, potentially dangerous, and disruptive. Sure, concrete cutters can make some noise, but they are much quieter than the alternative.

Safer

Concrete dust is a known health hazard, so it makes sense to minimize this as much as possible. Instead of paying for an explosion of dust, you can have a controlled cut that is safer for the people in the area. Bluegrass saws use water to cut in a “wetted” condition, and the resulting slurry is efficiently captured and contained.

More Economical

Because concrete cutting is more precise, it can be the best option economically. You are only removing the concrete you don’t need.

Examples of Concrete Cutting Projects

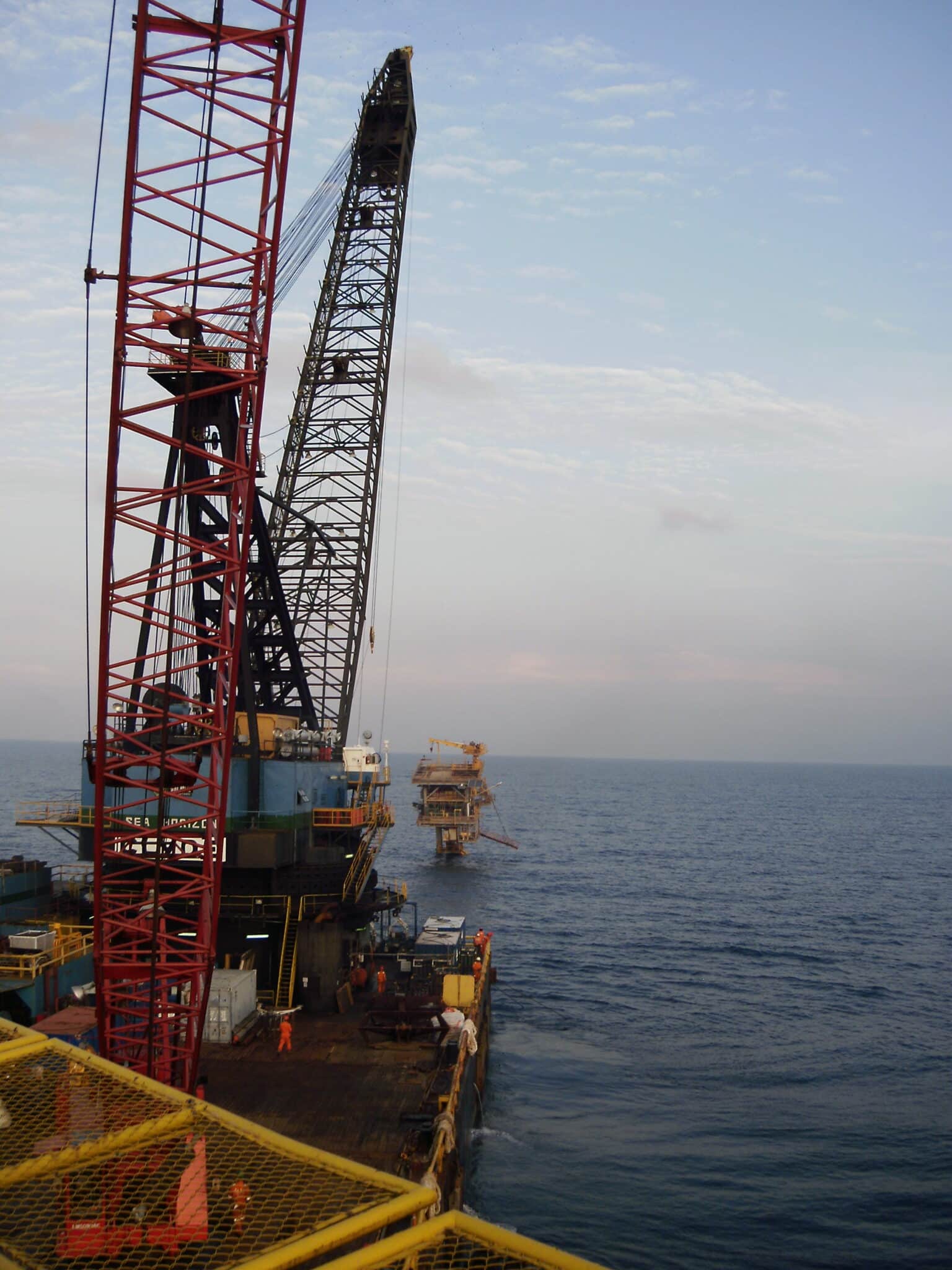

Bluegrass Bit Company is known as a global pioneer in the field of precision demolition. Our specialized concrete cutting equipment works on land, deep underwater, and under the most extreme conditions. Here are just a few examples of our concrete cutting projects.

- Gross Reservoir Dam Expansion — This is an ongoing project in support of Denver Water’s Gross Reservoir Expansion, which will triple the reservoir’s capacity by raising the height of the dam by 131’. In 2022, we assisted with removing the dam’s ogee crest through precision concrete cutting and concrete block removal.

- Humboldt Bay Nuclear Plant Decommissioning — We assisted with removing a 250’-tall ventilation stack at this nuclear power plant by cutting it into ring sections under harsh conditions and removing them from the premises.

- Arecibo Observatory Tower Repairs — This observatory located on a mountaintop in Puerto Rico required extensive repairs after damage to the dish. We used diamond-wire saws to cut damaged towers into smaller pieces for removal by crane.

- Pecan Island Compressor Base Cut — We helped remove a 90,000 lb. compressor on Pecan Island that sat on l-beams, which had been leveled using concrete grout in varying depths. We cut the base using diamond-wire technology, which allowed the compressor to be removed while remaining intact.

Contact Bluegrass Bit Company for Your Precision Concrete Cutting Needs

If you have a need for precision demolition, Bluegrass Bit has the experience, capabilities, and resources necessary to take on your job, anywhere in the world. We offer diamond-wire sawing, concrete shaving, core drilling, and other precision demolition services to clients in heavy industrial, offshore, heavy metal, nuclear, heavy civil, and other industries. We were the first demolition company to use diamond wire saws for controlled demolition in the 1970s.

Our more than four decades in the business have made us a global authority in the demolition and decommissioning business, and we are known for our advancements in diamond-wire sawing as an alternative to using explosives. Contact us today to discuss your project and learn more about how we can help you achieve your goals.