If you’re in the construction, mining, utilities, or infrastructure industry, it’s likely that your project will eventually require concrete core drilling. This particular service has revolutionized the construction and demolition process in many ways. Here is what you need to know about concrete core drilling, the different purposes it can serve, and examples of some of our projects using this service.

If you’re in the construction, mining, utilities, or infrastructure industry, it’s likely that your project will eventually require concrete core drilling. This particular service has revolutionized the construction and demolition process in many ways. Here is what you need to know about concrete core drilling, the different purposes it can serve, and examples of some of our projects using this service.

What Is Concrete Core Drilling?

Concrete core drilling, also called concrete coring, is the process of removing a cylindrical section of concrete from a structure or wall. This action is most often performed on walls, ceilings, and floors.

Concrete core drilling must be done safely and carefully. A mistake could compromise the wall’s load-bearing ability or the entire structure. Once the hole is drilled, the result should be perfectly smooth and round.

How Concrete Core Drilling Works

Concrete core drilling requires a specialized tool called a core drill. The tool’s purpose is to create large holes in masonry surfaces like concrete, stone, brick, and cement. A core drill looks like a hole saw, but the drill bits used will be either diamond or carbide, depending on the application.

Before core drilling takes place, there is usually a test called GPR scanning. This is short for ground-penetrating radar. It’s a way to get a closer look at the inside of the concrete to ensure it is structurally sound enough to sustain drilling.

By using a specialized bit and core drill, a circular section of concrete is drilled and then removed from the structure. The drill is mounted in a way that secures the machine and ensures a clean cut. As the drill’s shaft rotates, it cuts into the concrete or other material as deep as required.

The core created by the drill is called a “slug.” Depending on its size, it might be removed whole or in pieces. The resulting hole may be used for a variety of purposes.

Uses for Concrete Core Drilling

Concrete core drilling has a wide range of applications. Nearly every new construction project, renovation, or demolition will require cutting concrete cores. Some of the most common uses for concrete core drilling include the following.

- Creating holes for floor drains, heating and gas pipes, storm drains, and other plumbing

- Creating openings for electrical conduits, feed wires, and other electrical needs

- Creating holes for mechanical HVAC pipes and ducts

- Creating spaces for fiber optic, cable, and phone wire

- Creating holes for anchors and handrails

- Taking out concrete samples for testing

- Drilling water tanks or creating an opening for manholes

- Creating cut lines on major renovation and demolition projects

- Creating access holes for wire saw operations on precision demolition projects

Advantages of Using a Professional for Concrete Core Drilling

Concrete core drilling projects are complex and often hazardous. A simple mistake could be costly in terms of property damage and safety. Here are a few advantages of using a professional for your next concrete core drilling project.

Maintain Structural Integrity

If not done correctly, making cuts or drilling holes in concrete can have damaging effects on a building’s structure. A professional concrete drilling company will ensure your project is done in the correct manner.

100% Precision

Accuracy is a critical factor in handling concrete. If the work isn’t done correctly, it could lead to flaws or the need for future reworks. A professional will always use high-quality equipment and trained professionals to achieve accurate and precise results.

Environmental Considerations

The dust created by these projects can be hazardous to the environment and have the potential to cause serious illnesses. A professional will employ a wide range of solutions to take these environmental issues into consideration.

Ensured Safety

Many projects involving concrete cutting take place in extreme environments, and handling the tools themselves can be dangerous. When you work with a professional, you ensure the safety of everyone involved.

Examples of Concrete Core Drilling Projects

Bluegrass Bit Company provides concrete core drilling as one of our specialty services. Here is just a sampling of the many projects we’ve completed that involved core drilling.

- Gross Reservoir Dam Expansion — Most recently, Bluegrass Bit assisted with Project Phase 1 of the Denver Water’s Gross Reservoir expansion project, using core drilling to create wire holes for rail saws to cut a large section off of the dam’s ogee crest.

- San Onofre Nuclear Decommissioning — This was a precision demolition project in a seismically sensitive area, in which diamond wire access holes were core drilled through the 3′ walls to facilitate controlled deconstruction.

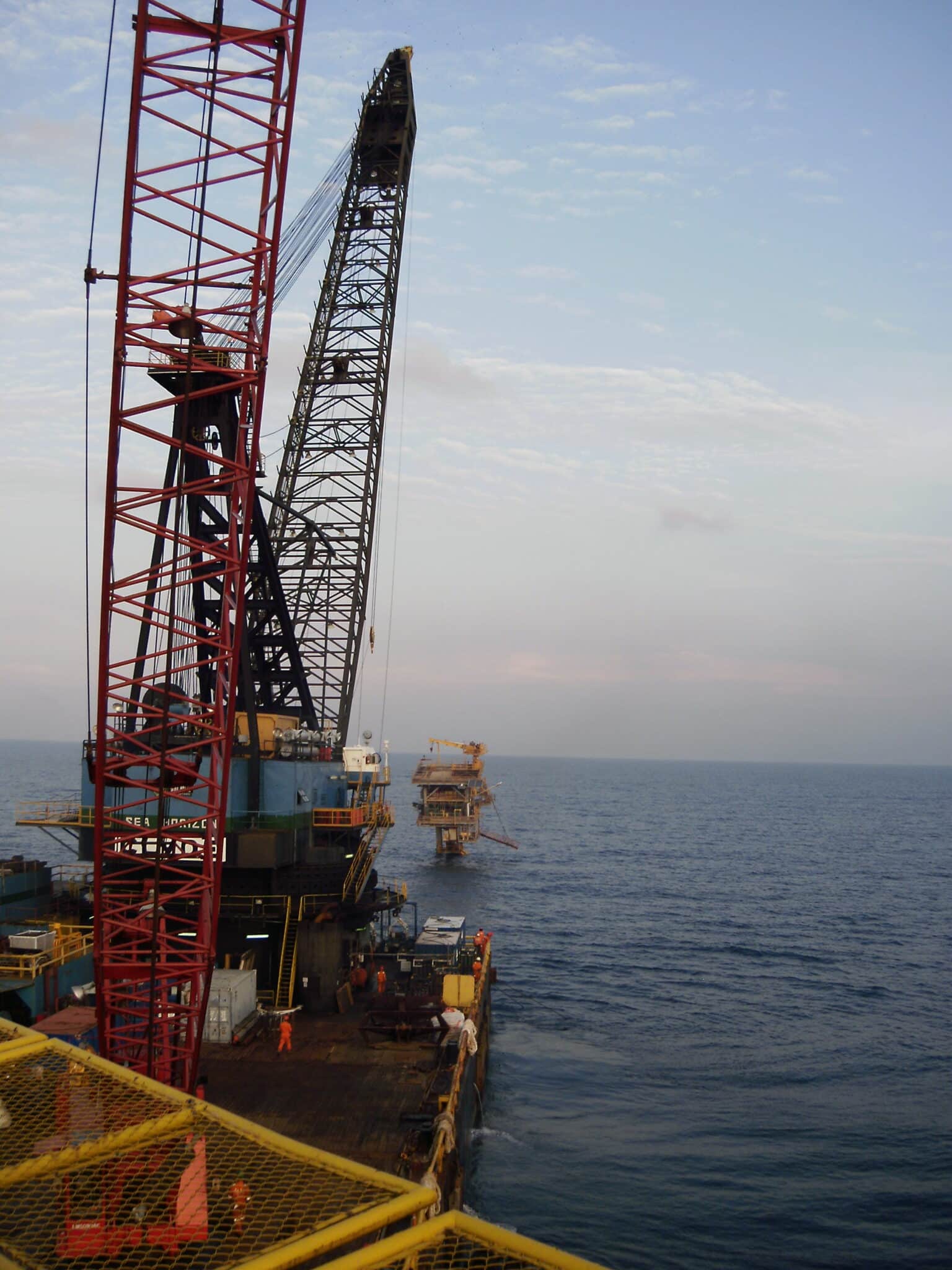

- CDM Topside Compressor Base Cuts — Bluegrass Bit removed compressors from the operating platform of a structure in the Gulf of Mexico. Our technicians core drilled 2″ deep holes that were 8″ in diameter to create a controlled cutline.

- Death Valley Stadium Expansion — In 2004, our company was involved in the expansion of the LSU “Death Valley” stadium in Baton Rouge, LA. Our crews used core drilling to remove the main support columns and concrete beams related to the removal of the west upper deck of the stadium.

- San Francisco Oakland Bay Bridge — When the East Span of the San Francisco Oakland Bay Bridge was replaced, it left a nearly 2-mile-long line of concrete piers that required removal. Bluegrass Bit core drilled, and then cut each pier into four smaller blocks for removal.

Contact Us for Expert Concrete Core Drilling Services Worldwide

Concrete core drilling takes years of experience to perform safely and properly. It’s never a good idea to attempt to alter concrete on your own. Instead, hire a seasoned professional so the job is done right.

Bluegrass Bit Company offers quality core drilling services to clients worldwide. Since 1979, our company has become well-known for its innovative techniques for cutting and removing concrete. Our core drilling technicians and equipment are capable of drilling cores up to 42″ in diameter at any angle and up to depths of 50′. Contact us today to discuss your project.