Concrete is a construction material with incredible compressive strength used to build everything from streets and sidewalks to industrial and commercial buildings to bridges, dams, and piers. When construction and renovation projects involve concrete in its various forms, in most cases, the planning and executing of the project will require removing, altering, or cutting concrete in some way.

Concrete is a construction material with incredible compressive strength used to build everything from streets and sidewalks to industrial and commercial buildings to bridges, dams, and piers. When construction and renovation projects involve concrete in its various forms, in most cases, the planning and executing of the project will require removing, altering, or cutting concrete in some way.

A diamond wire saw is a type that rotates cable strung with diamond-embedded beads. The cable and beads are coated with a thin layer of rubber, which contributes to durability, particularly in wet or marine environments The entire strand of cable, beads, diamond chips, and coating is known as “diamond wire.”

Due to its appearance, it is often referred to as “rope,” giving rise to the industry term “rope sawing.” The diamond wire is run through wheels and pulleys on the saw, allowing the operator to adjust tension, speed, and cutting depth.

When most people think of saws, they picture a bandsaw or reciprocating saw. The diamond wire saw is different. Rather than operating with a fixed blade, a diamond wire saw accomplishes the cut by looping the diamond wire around the object to be cut or threading the wire through a core hole to achieve the required loop configuration.

Using Diamond Wire Saws to Cut Concrete

Diamonds are one of the Earth’s hardest substances, which is why they are an effective tool for concrete cutting and other hard materials, including metal. Beyond the obvious advantage of diamond wire cutting through concrete, diamond wire saws are ideal for this work for several additional reasons.

Speed

Cutting through concrete with some tools can be a slow, tedious process, but diamond wire saws work in a way to expedite the concrete cutting project.

Versatility

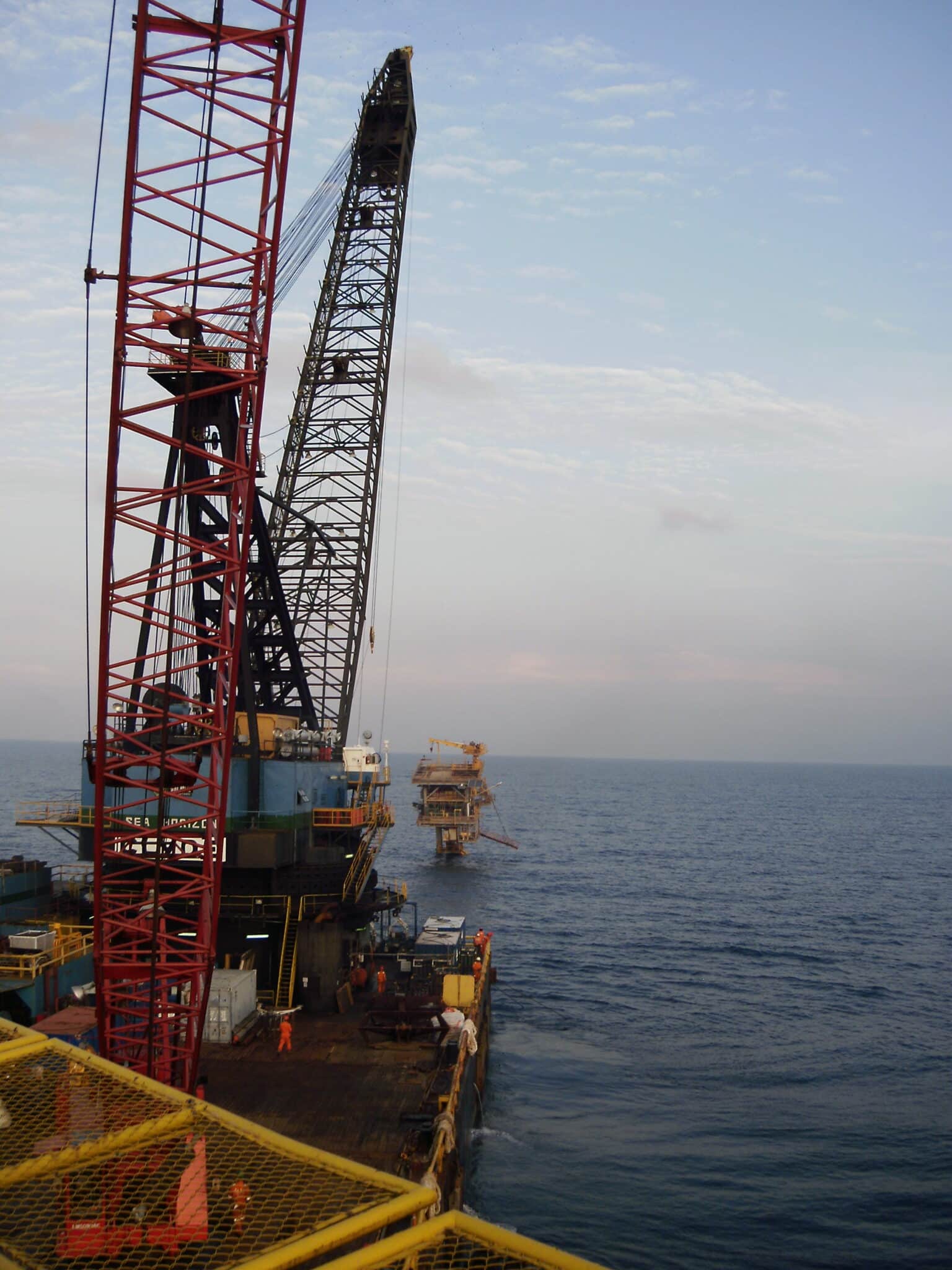

These saws can be configured in various ways; they operate underwater, suspended in the air, and in a wide range of temperatures and weather conditions.

Tight Space

Because diamond wire saws are configured on the job to suit the job, they can be used in locations with limited space and access. The operator, control panel, and power supply can, and often are, positioned a distance from the object being cut.

Precision

Rather than using explosion as a tool on the concrete demolition job, you can make precise cuts with diamond wire saws and segment the object into pieces sized for removal.

Minimal Vibration

These saws operate with minimal vibration, allowing them to be used on jobs where adjacent concrete structures might be damaged by vibration.

Minimal Dust

There are several techniques for minimizing and capturing the airborne effluents created by diamond wire concrete cutting, including HPV vacuums set up at the point of contact and sunning water on the wire at the cut site.

Durability

A significant benefit of diamond wire saws is their inherent robustness and durability. These saws can withstand punishing conditions, including marine climates and extreme temperatures. Because they are durable, downtime is rare, making diamond wire saws a cost-effective concrete-cutting option.

Safety

Using a diamond wire saw is safe for the operator and other people on the job site. A cutting plan created to minimize breakage and chipping is always a preferred option. These saws also produce less noise and dust than other concrete-cutting options.

These are all safety issues. Too much noise can damage hearing and lead to accidents from other hazards. Also, dust from concrete is a known health hazard and, consequently, something to avoid.

Concrete Applications for Diamond Wire Saws

Diamond wire saws can easily cut through hard materials and are the preferred choice for cutting through the toughest items, like concrete, masonry, rebar and other metals, and stone. Wire saws are the best option for cutting objects flush with an existing structure or in situations with restricted access, such as beyond narrow doorways and corridors and tight quarters such as hydroelectric dams, ships, and nuclear facilities.

Various industries have a frequent need for concrete cutting using diamond wire saws. These include the heavy civil, heavy industrial, nuclear, and offshore industries. Other industries use this tool and these cutting processes for decommissioning and precision demolition solutions.

Examples of Concrete Cutting Projects Using Diamond Wire Saws

Here are a handful of examples of large-scale industrial projects that Bluegrass Bit Company has completed over the years using diamond wire saws.

Gross Reservoir Dam Expansion

In Project Phase 1 of Denver Water’s Gross Reservoir expansion project, Bluegrass Bit helped remove the dam’s ogee crest, which measured 160’L x 28’W x 13’ H. After drilling 4” wire access holes, we used diamond wire saws to cut vertical slots and then horizontal cuts into the dam to remove 20,000-60,000 lb. blocks for removal.

Humboldt Bay Nuclear Plant Decommissioning

Due to seismic concerns, PG&E needed to remove a 250’ ventilation stack at the Humboldt Bay Nuclear Plant. Operating on an elevated platform, Bluegrass Bit removed large ring sections of the ventilation stack using diamond wire saws and cut the concrete into smaller segments for disposal.

Tallulah Falls Dam Plug Removal

The Tallulah Falls project involved cutting and removing a plug in the dam face for a new pipe insertion. Using a crane, Bluegrass Bit cut and pulled the plug using a diamond wire saw. We then cut the removed plug into smaller pieces of manageable dimensions.

Hydromill Rescue in Boston

A construction company’s hydromill became inoperable and wedged 70’ underground during the winter in Boston. The company turned to Bluegrass Bit for assistance. The equipment was wedged against an I-beam. Our team used diamond wire saws to cut through an adjacent concrete wall, providing access to the I-beam for safe removal.

Precision Concrete Demolition from Bluegrass Bit

The Bluegrass Bit team and diamond wire saw equipment can and will meet your concrete cutting needs. Founded in 1979, we pioneered using diamond wire saws for the non-explosive and underwater cutting of concrete and other materials.

Our business is well-known for revolutionizing this industry and creating customized saws to fit each job. Our innovative and patented diamond wire saws are used in various applications across all major industries. From our headquarters in Alabama, we offer our services to clients around the globe.

Every job we take on is supported by a highly-trained and experienced team of engineers, mechanics, machinists, and project managers to ensure superior results and project safety. Contact us today to learn more about our diamond wire sawing services.