There are times when a part of a structure needs to be torn down or reworked to meet certain needs. It doesn’t always make economic or functional sense to rip everything apart and start from scratch. The solution is selective demotion.

There are times when a part of a structure needs to be torn down or reworked to meet certain needs. It doesn’t always make economic or functional sense to rip everything apart and start from scratch. The solution is selective demotion.

Selective demolition, also referred to as precision demotion, is the process of demolishing specific materials or zones within a building or structure. It’s slightly different from interior demolition, which involves the complete demo of all interior elements of a structure. For example, a structure may need to be made higher, lower, wider, or safer.

Selective demolition can also refer to the precise process of taking a structure apart. Instead of using explosives to blow it up or a crane to knock it down, this process is more precise. In other words, selective demolition techniques are preferred to preserve usable areas of the property and avoid the collateral damage that explosives can cause.

How Selective Demolition Works

Every selective demolition project is different, but here are a few key steps that characterize most successful projects.

Planning and Surveying

Any project that involves demolition will also require a significant amount of planning and preparation. Depending on the nature of the project, the contractor might need to invest in extensive site surveys and materials testing.

The results of the testing and surveys will allow the team to create a detailed plan for execution. Specifically, what equipment, experience, and expertise will be required for the project? How long will it take to complete? What are the inevitable challenges that still require addressing?

“Cutting and Capping” Utilities

Another vital step to take before launching the project is to cut and cap any existing utility lines. This ensures there is no damage to the remaining structure during the project. Also, any part of the structure that will remain in operation could do so if this step is planned correctly.

Obtaining Licenses, Permits, and Insurance

Many selective demolition projects are massive undertakings. They may require separate permits or the company may have to adhere to various state and federal regulations. Insurance and bonding for the specific project is generally a requirement.

Emphasizing Safety

Precision demolition can also be dangerous work. One of the trademarks of a successful project is a company’s ability to achieve the desired goals without any major incidents or injuries. This happens through careful planning, experience, and strict safety procedures.

Planning for Removal

One of the major benefits of selective demolition is that it’s a cleaner and more sustainable option. Instead of blowing everything to pieces, you have the opportunity to salvage and even reuse materials. Assuming you don’t want to reuse the materials, at least other parts of the property or structure won’t be damaged or destroyed by the process. It’s also a more environmentally friendly option.

When Selective Demolition Might be Applicable to a Project

Selective demolition is applicable to a variety of projects in a variety of industries. Here are a few examples.

- Heavy industrial — Various heavy industrial industries use selective demolition for projects related to power plants, steel mills, pulp and paper mills, and refineries.

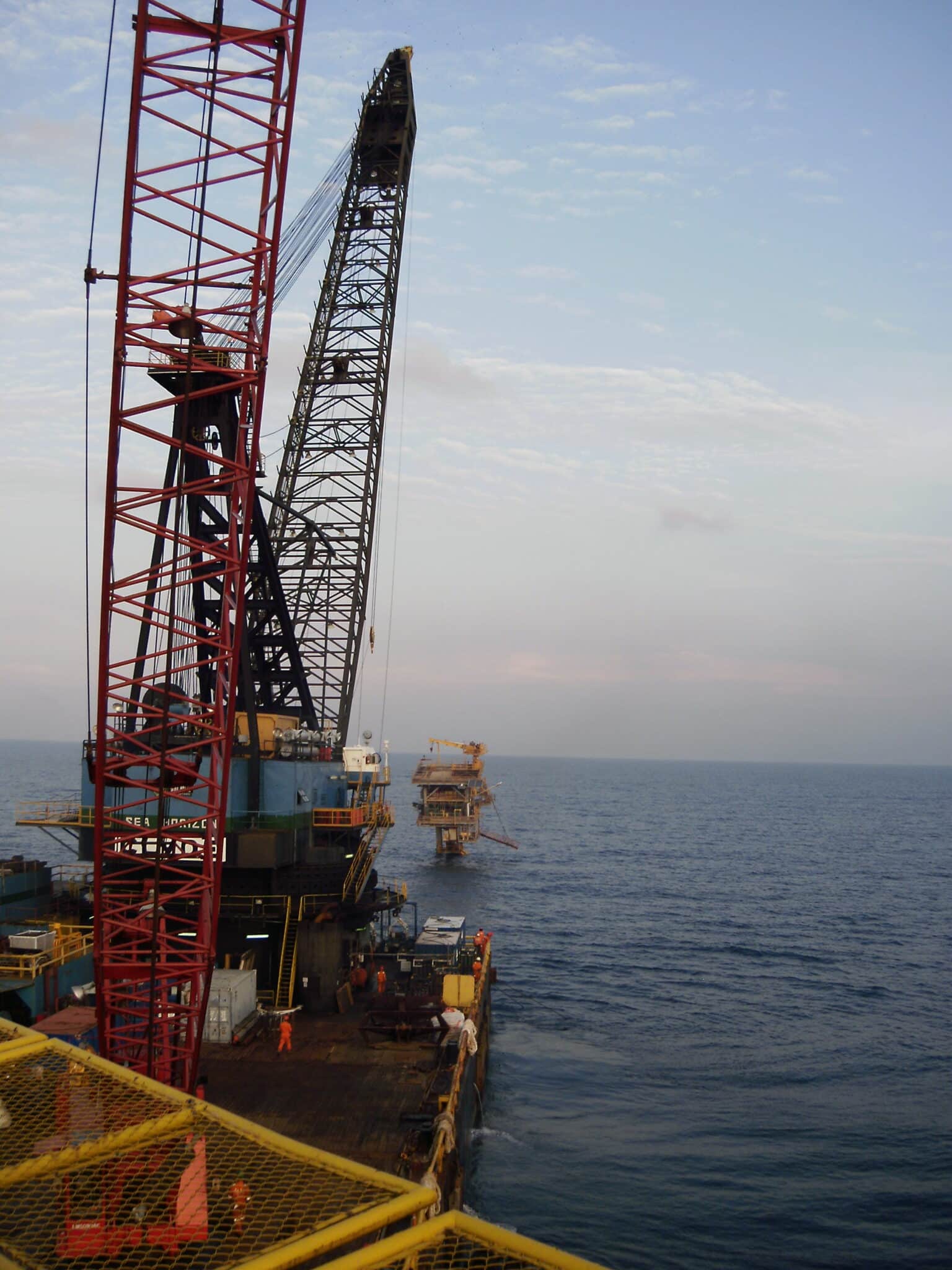

- Offshore — Selective demolition even takes place offshore for things like marine applications, topside modifications, and platform segmentation.

- Heavy civil — The heavy civil industry uses precision demolition for projects related to ports, locks and dams, and highway bridges and railroad bridges.

- Nuclear — In the nuclear field, these services can be used for decommissioning, seismic upgrades, and steam generator replacement.

- Heavy metal — Heavy metal industries use these services for projects related to decommissioning and size reduction. Selective demolition is also used to cut large metal structures for forensic testing.

Examples of Some of Our Selective Demolition Projects

One of the best ways to understand how selective demolition can work for your business is to understand how it has benefited others. Here is just a small sampling of some of Bluegrass Bit’s many precision demolition projects.

- Gross Reservoir Dam Expansion — Bluegrass Bit is currently assisted with Project Phase 1, where we used core drilling and diamond wiring sawing to remove the dam’s ogee crest with the goal of raising the dam’s height by over 130’.

- Arecibo Observatory Tower Repairs — We traveled to Puerto Rico to remove the disintegrated topics of towers from which a reflector dish had been suspended. The crew used diamond wire sawing to cut the concrete into manageable pieces for removal.

- Nuclear Ship Savannah Renovation — Anchored in Baltimore, MD, Bluegrass Bit assisted with cutting interior openings in the world’s first nuclear-powered ship to gain access to the reactor as part of the renovation project.

- Lake Mathews Water Intake Structure Modifications — This was a precision demotion project due to concerns that an earthquake could lead to structural failure. We used core drilling and wire sawing above and below the waterline to cut the concrete structure into manageable blocks.

When to Call in the Professionals for Your Project

Selective demotion is a highly specialized form of destructive work. It involves proprietary processes and tools as well as the expertise of skilled workers with years of experience in the industry.

Bluegrass Bit has built a global reputation as a leader in precision demolition projects. We have the capabilities, resources, and experience to take on the concrete and metal cutting and drilling elements of demolition jobs of any scope, anywhere in the world.

We offer diamond wire sawing, robotic hammering, core drilling, concrete shaving, and rail saw services to clients in various industries—onshore, offshore, and underwater. Contact us today for more information about how our specialized services can help your business achieve its goals.