Diamond wire saws have been around for some time. These tools were initially used to cut through stone in quarries and later modified for other building and demolition purposes.

Diamond wire saws have been around for some time. These tools were initially used to cut through stone in quarries and later modified for other building and demolition purposes.

However, there is another type of saw that has proven vital to the completion of complex projects: the diamond wire rail saw. A diamond wire rail saw is a rail saw that uses a diamond wire to cut through a variety of surfaces. These are customized and versatile tools that deliver the most accurate concrete and metal cutting available.

A rail saw is a series of metal beams, or rails, assembled to fit a particular structure. Rather than using a standard diamond wire saw to approach a job, rail saws are a superior means of deploying diamond wire within a rail framework to cut concrete structures. The wire is moved across a surface using wheels, pulleys, and hydraulic motors. The saw operates by rotating the diamond wire to penetrate the concrete.

There is a distinct difference between a diamond wire saw and a diamond wire rail saw. A diamond wire saw is a free-form saw that has diamond-embedded beads on a cable strung around a structure for cutting. Many people refer to these as “rope saws” due to their appearance. The diamond wire rail saw was designed and patented by Bluegrass Bit. No other company has created or uses diamond wire in a rail saw that functions in this manner.

Advantages of Using a Diamond Wire Rail Saw

Bluegrass Bit invented the diamond wire rail saw, patented it, and is the only company building and using it. Because it’s our creation, we have the ability to modify it, reconfiguring the dimensions to meet the client’s needs and the job specifications.

Partnering with Bluegrass for your precision demolition needs means you will be working with a company using superior equipment. Your job will be done safely, precisely and on schedule, using a diamond wire saw customized for the job.

Rather than drilling core holes, we can drop the rail saw onto a concrete block and push the wire using hydraulic motors and wheels to create the desired cut. By eliminating that step, a diamond wire rail saw saves significant time and money.

Uses for Diamond Wire Rail Saws

Diamond wire rail saws are excellent for projects requiring underwater cuts. They’re frequently used in heavy civil projects, cutting items like underwater bridge piles and concrete sills.

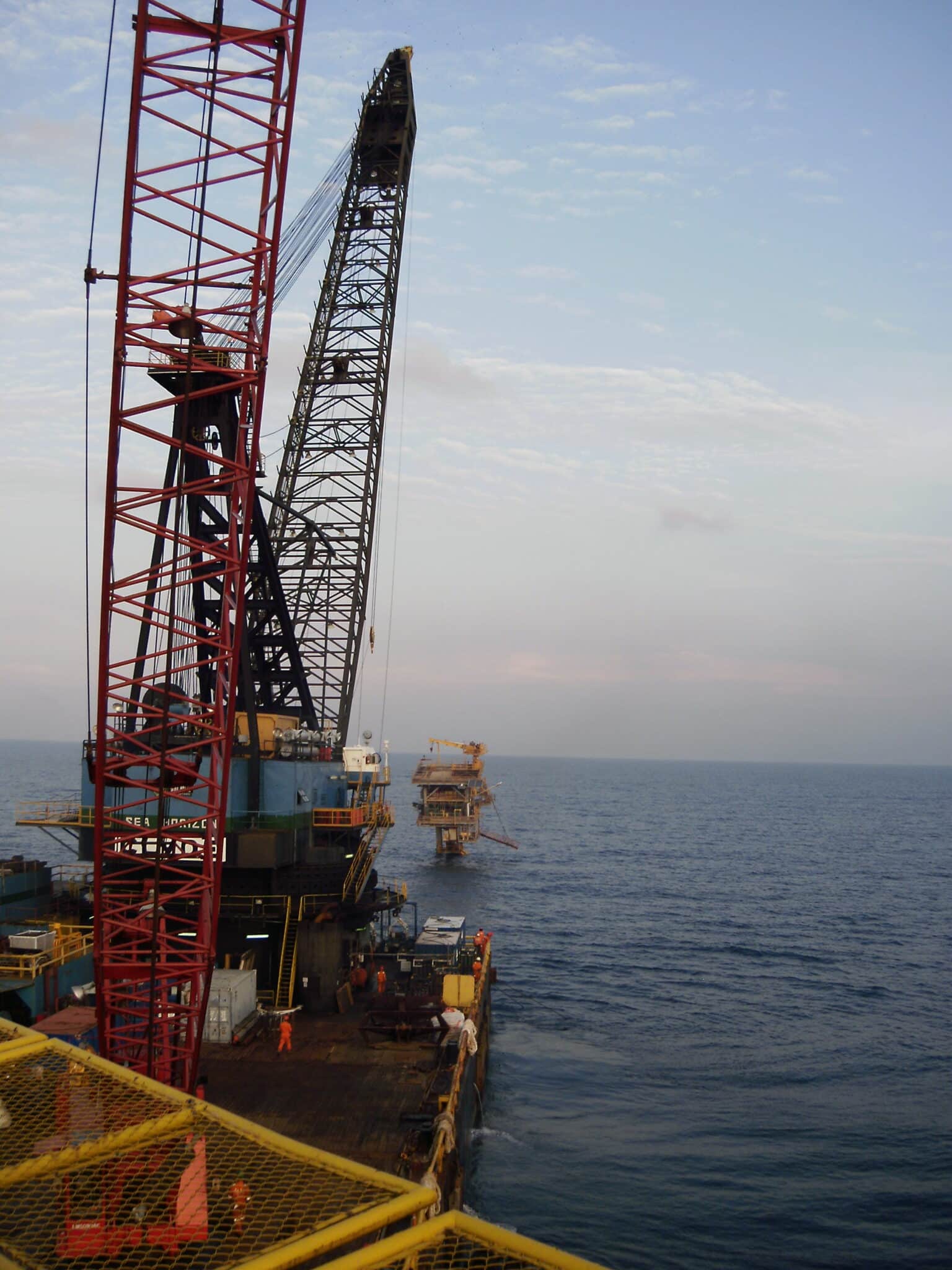

Rail saws are also used on offshore projects. While we have other saws able to handle some of these projects, we also customize rail saws when a job is large or complex enough to require one.

We work with private companies, contracting firms, and government agencies including the Department of Defense, Department of Energy, and the U.S. Army Corp of Engineers. We decommission structures as diverse as military vessels, bridges, and nuclear reactor heads. Our saws are also used to segment blocks for removal on structures undergoing modification, such as locks and dams, stadiums and foundations.

Projects Using a Diamond Wire Rail Saw

Two recent examples of projects Bluegrass successfully completed using diamond wire rail saws:

Blount Island Sill Removal

Located in Blount Island, FL, this US Marine Corp Support Facility needed to remove an underwater concrete sill that was impeding the ability of resupply vessels to fully access the location.

Bluegrass Bit was awarded this project by the U.S. Army Corp of Engineers to remove concrete blocks located 50 feet underwater. The blocks were 426 feet long, 32 feet wide, and 15 feet tall. The diamond wire rail saw was custom-built for this job.

Divers operated at 50-foot plus depths with minimum visibility. The job consisted of 27 vertical cuts and 28 horizontal cuts, with cut times averaging anywhere from 12-15 hours. The average size of a cut block was 32.5′ W x 15′ L x 10′ H.

After simulating the job on land with the customized saw, our team successfully completed the project on-site, on schedule, and without breaking a single diamond wire.

Gross Reservoir Dam Expansion

Bluegrass Bit was contracted to assist with Denver Water’s Gross Reservoir Dam Expansion project in Boulder County, CO. In Project Phase I, the task was to remove the dam’s ogee crest, which measured 160′ L x 28′ W x 13′ H.

This was another project taking place in extreme conditions; rather than operating underwater, this job location was high on the dam’s face. Multiple saws ran simultaneously to cut cement blocks weighing up to 60,0000 lbs. for removal.

Our customized diamond wire rail saws were used to make precise vertical and horizontal cuts. We also used traditional diamond wire saws after drilling core access holes. This enabled us to accelerate cutting times and create a pattern allowing the installation of the rods needed for the safe removal of the cut blocks.

Using our patented rail saws combined with the expertise of our technicians, we were able to cut through over 20,000 SF of concrete at a rate of roughly 20 SF/hr with no safety incidents.

Contact Bluegrass Bit for Your Precision Demolition Needs

If you have a unique or precision demolition project, learn more about how Bluegrass Bit can help. Since 1979, our team of experienced engineers and demolition experts has been serving clients’ needs in a broad spectrum of industries.

Not only are we the pioneers of many precision demolition techniques, we are also the only company offering our customers the option of accomplishing their goals by using diamond wire rail saws. Our solutions cut through the most challenging structures items in the harshest conditions with proven success, saving you time and money. Contact us today to learn about our services.