Challenge

Isolating the areas to be demolished from the surrounding areas which would remain, in order to maintain their structural integrity.

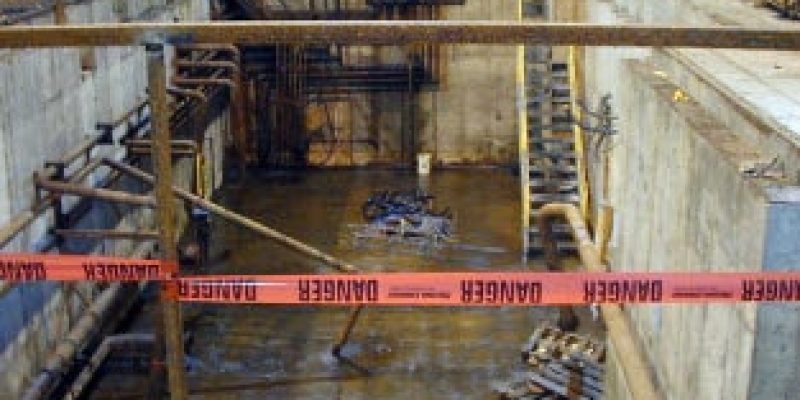

Phase I: Remove 65-70% of the existing mill tunnels and pits to make way for new walls and structures. We first drilled a core hole 14’ deep, fed diamond wire through it, and then commenced a vertical cut that isolated a large block from the foundation. That block was cut into segments and removed. We then hammered 250 cubic yards of concrete into rubble using a Brokk 330 robotic hammer.

Phase II: In the roughing mill an estimated 936 cubic yards of concrete trenches and foundations needed to be demolished and removed. To isolate that slab, we flat sawed the perimeter to a depth of 8.” We also removed a series of 18’ tall concrete stands by wire sawing into blocks and rigging for removal.

Phase III: 250 cubic yards of a concrete wall in the reheat furnace was removed after Bluegrass cut it into blocks.

Phase IV: In the cooling pit we wire sawed 80 small concrete foundations and removed 140 cubic yards of furnace foundation.

Over the course of 3 hot months, 4 Bluegrass operators wire sawed approximately 1,000 square feet, flat sawed 1,500 linear feet, drilled 14-foot-deep core holes, and hammered 1,800 cubic yards of concrete. This job showcasing several techniques used for effective concrete demolition was successfully completed on time, under budget, and with no accidents.